It's super fast! High speed visual inspection of nail clippers

The cap of a nail clipper refers to one end of the nail clipper, usually used to cover the blade part of the other end. Nail clipper cap is an important part of nail clipper, in addition to protecting the blade, but also play a beautiful and convenient role. Proper use and maintenance of nail clippers can extend the service life of nail clippers.

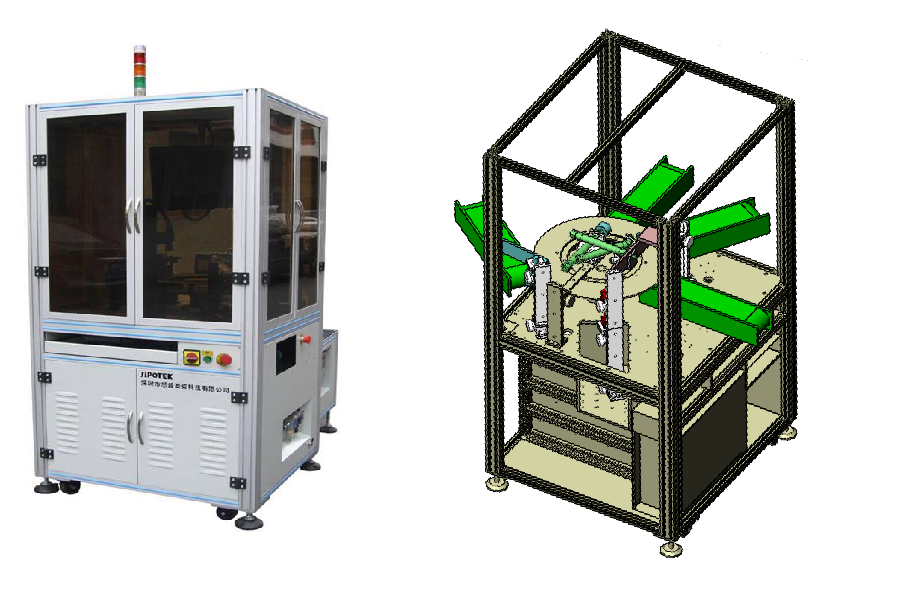

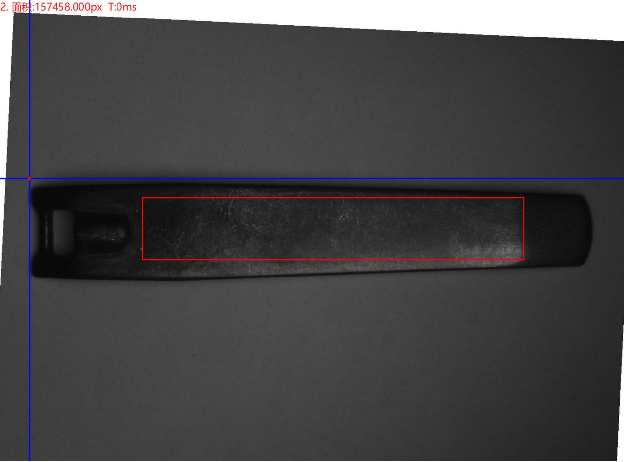

This case is to test the appearance of the nail clipper cap with a maximum size of 75mm* 10mm* 3mm. Poor plating at the bottom, poor plating at the top, side thickness and color difference occurred during the processing of the nail clipper cap. For the defects of this product, we recommend the use of high-speed visual inspection equipment. Its inspection efficiency is no less than 80 pieces per minute (depending on the product feed speed).

High-speed visual inspection equipment is a device specifically designed to quickly detect and analyze the visual characteristics and quality of products or objects. High-speed visual inspection equipment plays an important role in industrial production and quality control, providing efficient and accurate product inspection solutions.

Device function

Fast and efficient: With high frame rate and fast processing capability, it can complete the inspection of a large number of products in a short time.

Accuracy: High-resolution cameras and sophisticated image processing algorithms ensure accurate and reliable inspection results.

Automation: It can be integrated with the production line to achieve real-time detection and feedback in the automated production process.

Multi-function: It can be customized according to the requirements, suitable for different industries and application fields.

Equipment composition

Visual inspection software

Industrial computer

display

Industrial camera

Camera adjustment servo module

Industrial lens

illuminant

Detection platform

Servo motor

Control system

PLC motion collaboration

Detection effect

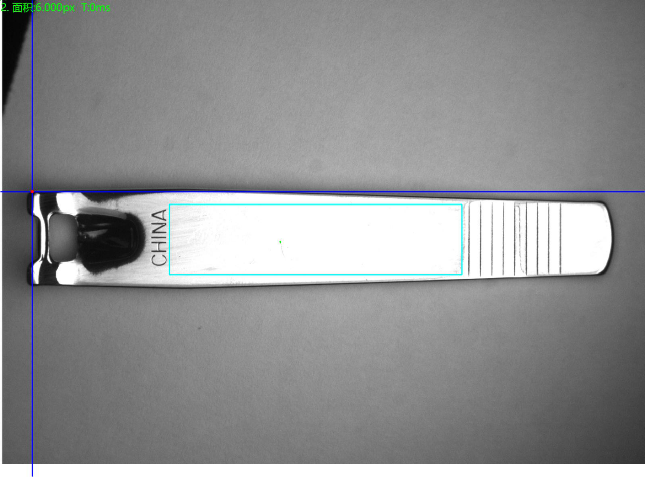

Bottom positive light detection good product analysis diagram: OK

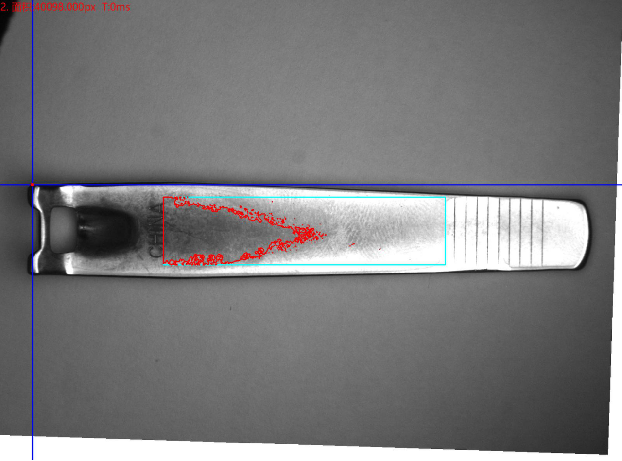

Bottom positive light detection of defective products analysis diagram: NG Bad characteristics: poor plating analysis results: detectable

Top positive light detection good product analysis diagram: OK

Top positive light detection of defective products analysis diagram: NG Bad characteristics: poor plating analysis results: detectable

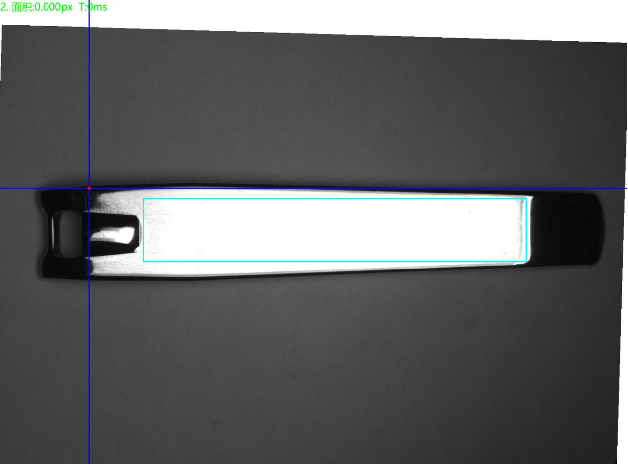

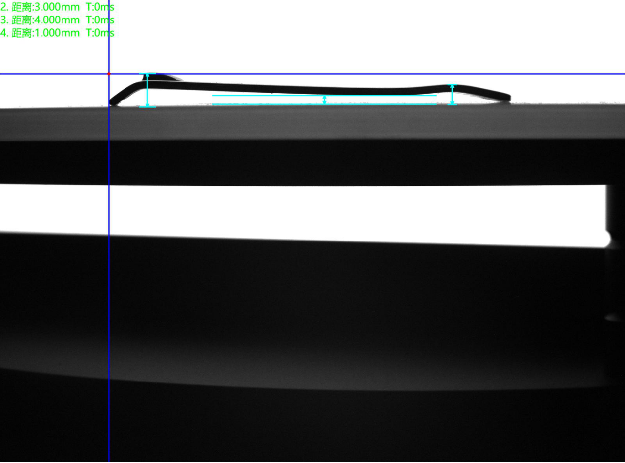

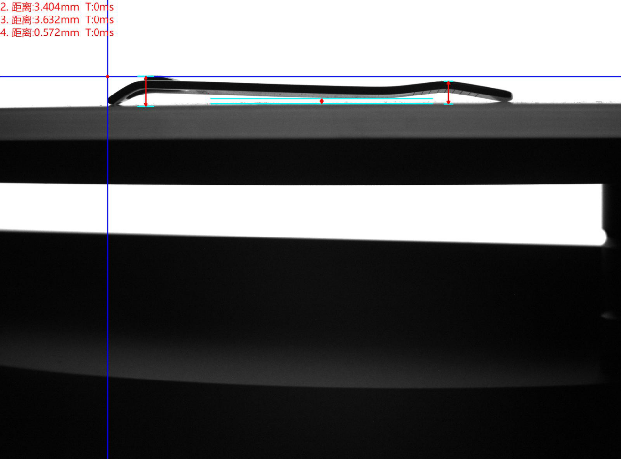

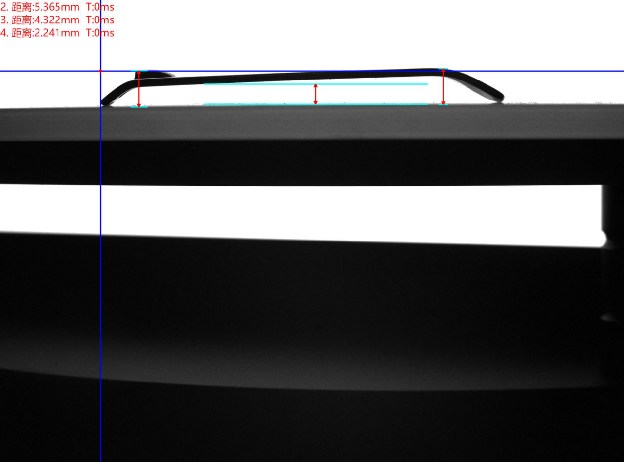

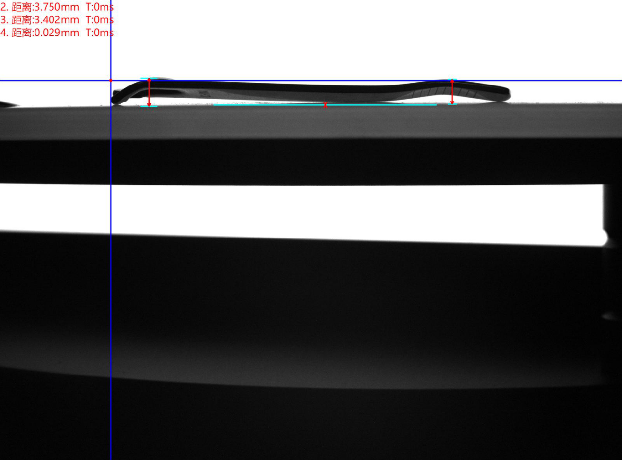

Side backlight detection good product analysis diagram: OK

Side backlight detection defective product analysis diagram: NG Defective feature: tail deformation analysis result: detectable

Side backlight detection defective product analysis diagram: NG Defective feature: tail bending analysis result: detectable

Side backlight detection defective product analysis diagram: NG Bad feature: Head deformation analysis result: detectable

System installation requirements

Inspection space for equipment placement: When installing the Siptech vision inspection system on the assembly line, it is necessary to ensure sufficient space for installation of equipment.

Ambient temperature: 0-50 degrees Celsius;

Air humidity: below 90% RH;

Electronic interference: Provide a place for the device with less electronic interference.

Power supply: AC 220V, 50Hz, power consumption < 1KVA.

-

Service hotline

13077808017